... the other way.

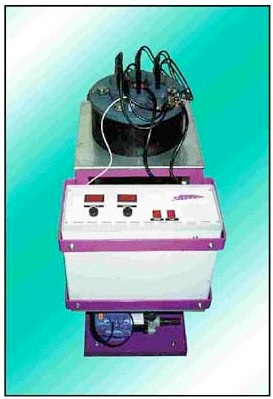

ECOSAVIOR

COPPER SULPHATE RECYCLING AND ELECTROLYTIC SELECTIVE CLEANING UNIT

This mobile unit can be connected to any copper plating tank for the chemicacl maintenance of electrolyte and keeping the balance of sulphuric acid and copper sulphate.

Copper sulphate recycling:

Reduction by backplating onto reusable cathode rods. This operation is necessary if the anode surface is larger than the cylinder surface (small cylinder in a big tank). This occurs without any effect on the level of sulphuric acid or hardness additive.

IMPORTANT NOTE: This unit should be used with chloride-free hardness additives.

Selective cleaning:

Continuous removal of foreign metal contamination in the electrolyte such as, Iron, Zinc, Tin, Nickel, etc. That effects the engraving properties of copper. (Additional analytical equipment required)

Copper cathode rods of 6mm in diameter are continuously plated until 40mm. The rods are then exchanged for new ones. The plated copper rods can be cut up and reused as the anode in any copper plating tank.

Current Control:

Maximum Current:

Circulation:

Safety Equipment:

Power supply:

Dimensions:

Directly by potentiometer or by voltage

100 A

35 litres per minute (3 bar)

Level control switch

230 V - 50/60 Hz

600 mm x 700 mm x 1250 mm

News

Machines

Automatisation

Grinding and Polishing

Copper Plating

Chrome Plating

Preparation

Quality Control